Pre Engineered Building- Prefabricated Building

500.0 INR/Square Foot

Product Details:

- Door Material Other

- Window Material sandwich Board

- Wall Materials Rock wool, Sandwich Panel, Aluminum sheet, EPS

- Open Style Other

- Dimension (L*W*H) Customizable as per project specification Meter (m)

- Insulation Other

- Connection Bolted or Welded Connections as per standard

- Click to view more

X

Pre Engineered Building- Prefabricated Building Price And Quantity

- 800.00 - 1500.00 INR/Square Foot

- 500.0 INR/Square Foot

- 1000 Square Foot

Pre Engineered Building- Prefabricated Building Product Specifications

- Heavy-duty concrete or customized steel deck

- Other

- Other

- 30-50 years depending on maintenance

- Other

- 0.15-0.25 KN/m2

- Bolted or Welded Connections as per standard

- Other

- Rock wool, Sandwich Panel, Aluminum sheet, EPS

- Other

- Other

- 50mm-150mm as per insulation requirement Millimeter (mm)

- sandwich Board

- Other

- Designed as per seismic zone required (typically Zone 3/4/5) VGA

- Up to 5 KN/m2 or as per design requirement Kilograms (kg)

- 0.57 KN/m2

- Other

- Customizable as per project specification Meter (m)

- RAL Shade as per customer requirement

- Villa, Workshop, Office

Pre Engineered Building- Prefabricated Building Trade Information

- Cash in Advance (CID), Cash Advance (CA)

- 8000 Square Foot Per Day

- 7 Days

- Asia

- All India

Product Description

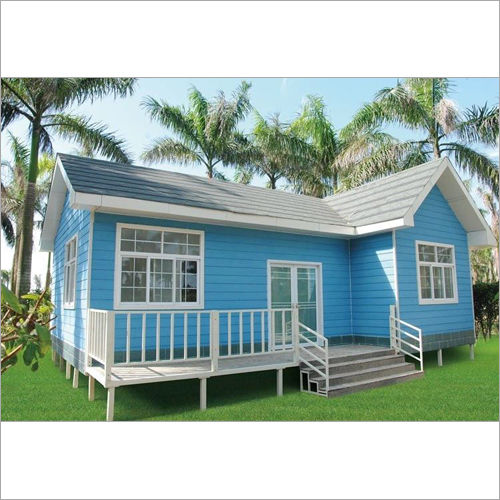

Pre-Engineered Building Prefabricated Building is employed in the construction of apartment buildings and multi-family housing complexes. Prefabrication is a critical component of construction industrialization. It is very simple to put together, requires less time, and is available in a range of sizes to fit any project, from sheds to garages to airplane hangars. Pre-Engineered Building Prefabricated Building is built at a factory and then transported to the project site to be erected. It is often used as the skeleton for a pre-engineered structure, although it may also be purchased ready to build and use.

Versatile Customization for Various Applications

Our prefabricated building solutions cater to diverse requirements across industrial, warehouse, factory, institutional, and commercial projects. From customizable eave heights (6m12m+), optimized bay spacing, and tailored wall/roof materials, every aspect can be adapted to suit your needs and project specifications. Choose from a variety of door and window styles, colors, and foundation options for a fully personalized structure.

Exceptional Structural Performance and Safety

Engineered to meet stringent safety standards, these buildings incorporate high-grade steel frames, galvanized coatings (up to 275 ), and robust fasteners to prevent corrosion. The design adheres to IS 800, IS 875, MBMA, and AISC codes, ensuring resilience against wind speeds up to 180 km/h and seismic activities as per Zone 3/4/5. Fire safety is thoroughly addressed in accordance with NBC and Factory Act norms.

Efficient Construction and Long-Term Value

Prefabricated buildings are fabricated and assembled swiftly off-site, significantly reducing construction timelines. With a lifespan of 3050 years given proper maintenance, these structures provide outstanding return on investment. Features such as energy-efficient insulation, advanced ventilation systems, and heavy-duty flooring ensure operational efficiency and reduced lifecycle costs.

FAQs of Pre Engineered Building- Prefabricated Building:

Q: How are pre-engineered buildings customized to suit different project requirements?

A: Pre-engineered buildings are highly adaptable, offering customizable dimensions, eave height, bay spacing, wall and roof materials, door and window styles, and color options. Structural load, insulation thickness, and facade choices can be tailored based on specific industrial, warehouse, or commercial needs.Q: What is the process for constructing a prefabricated steel structure?

A: The process begins with design and engineering as per project specifications, followed by fabrication of main frames, columns, beams, and purlins at the factory. Afterwards, the structure is transported, assembled on-site using bolted or welded connections, anchored to a concrete foundation, and finished with cladding, insulation, painting, and installation of doors, windows, and ventilation systems.Q: When is it ideal to choose a prefabricated building over conventional construction?

A: Prefabricated buildings are ideal when rapid completion, flexible design, and cost-effectiveness are priorities. They are especially suited for industrial, warehousing, and commercial projects with tight schedules, specialized requirements, or challenging site conditions.Q: Where can these prefabricated steel structures be used?

A: These buildings are suitable for a wide array of applications including factories, warehouses, commercial outlets, institutions, and other industrial setups. Their adaptability makes them a reliable choice across urban and rural locations, regardless of project scale.Q: What are the benefits of using high-grade steel and galvanized coatings?

A: High-grade steel ensures superior strength and load-bearing capacity, while galvanized coatings (up to 275 ) provide enhanced resistance to corrosion and harsh environmental conditions. This combination extends the structures lifespan and reduces maintenance costs.Q: How does the building ensure fire and wind resistance?

A: The structure is designed according to NBC and Factory Act fire safety standards, using fire-retardant insulation and materials. Wind resistance is addressed during engineering, allowing the building to withstand speeds up to 180 km/h and meet relevant IS, MBMA, and AISC codes.Q: What is the expected lifespan and maintenance requirement for these buildings?

A: When properly maintained, prefabricated steel buildings can last between 30 and 50 years. Maintenance typically involves periodic inspections, paint touch-ups, checking for corrosion, and ensuring all connections remain secure.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email